Teflon butterfly valve for biogas PTFE butterfly valve Corrosion-resistant butterfly valve

- Model

- DN40-DN600

Item specifics

- Standard

- PN10/PN16/CL150

- Sample

- Free

- MOQ

- 1PCS

- Certification

- ISO9001/PED/CE/EAC/TüV

- OEM

- YES

- Color

- Accept Custom

- Certificate of origin

- YES

- 3.1 Material test

- YES

- Visit the factory

- Real-time video

- Guarantee period

- 3 Years

Review

Description

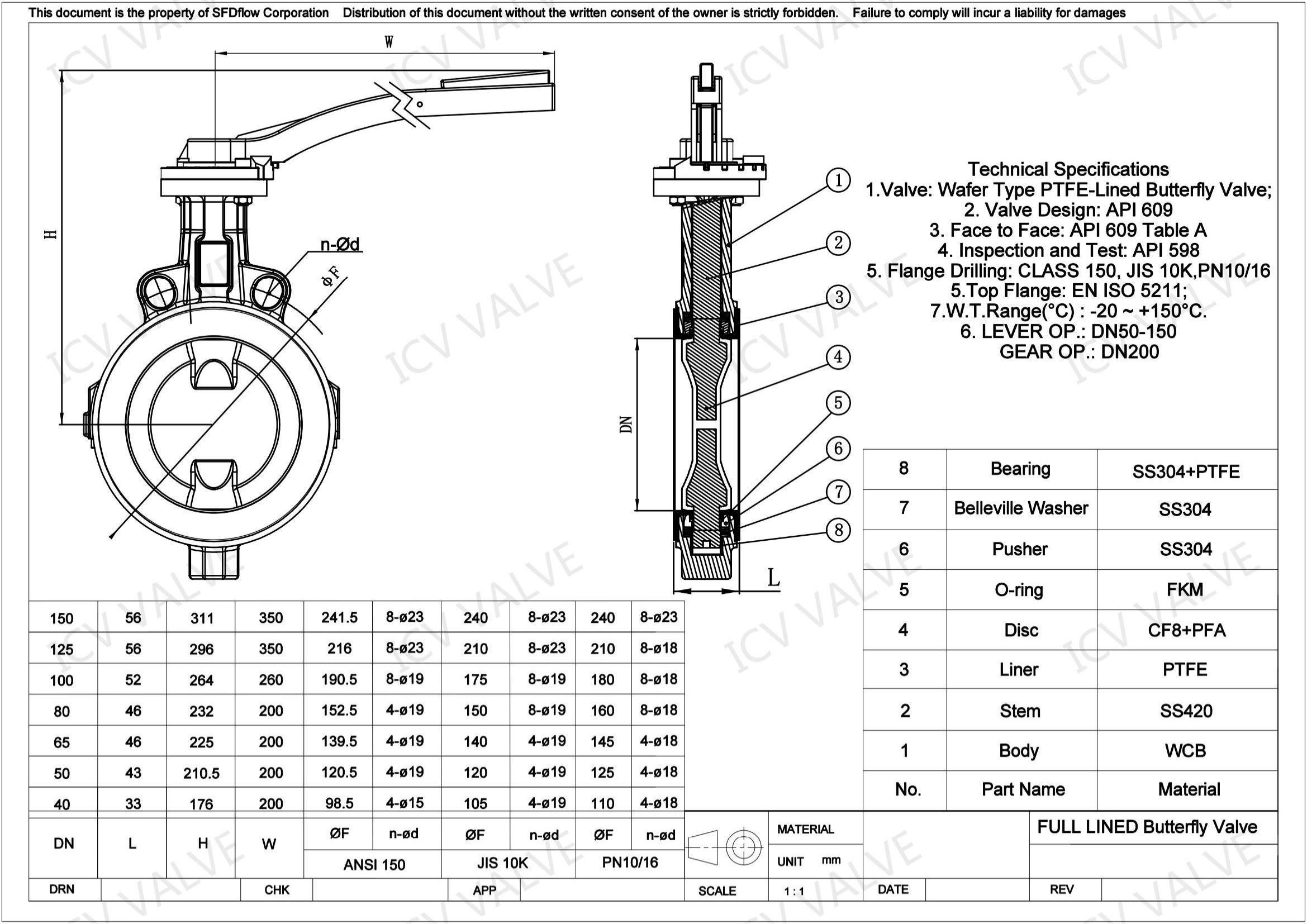

Custom Wafer Stainless Steel Butterfly Valve

Body Material

Cast iron GJL 250;Ductile iron EN-GJS-400-15

Disc Material

Stainless steel CF8M + PTFE

Sleeve

PTFE + FPM (Viton®)

Stem

Stainless steel 316

Joint

FRP (Fiber reinforced plastic)

Bushing

FRP (Fiber reinforced plastic)

Ring

Steel

Stem circlip

Steel

Operation

Lever Hand;Gear box

Wafer Stainless Steel Butterfly Valve

1. Butterfly valve has the characteristics of simple structure, small volume, light weight, material consumption, small installation size, quick switch, 90° reciprocating rotation, small driving torque, etc., used to cut off, connect and adjust the medium in the pipeline, with good fluid control characteristics and close sealing performance.

2.Butterfly valve can transport mud, at the mouth of the least liquid accumulation. Good sealing can be achieved under low pressure. Good regulation performance.

3.Butterfly plate streamlined design, so that the loss of fluid resistance is small, can be described as an energy saving product.

4.Valve stem is through rod structure, after quenching and tempering treatment, has good comprehensive mechanical properties and corrosion resistance, abrasion resistance. Butterfly valve open and close the stem only for rotary movement without lifting operation, stem packing is not easy to damage, reliable sealing. It is fixed with the butterfly plate cone pin, and the overhanging end is designed to prevent the stem from collapsing when the connection between the stem and the butterfly plate breaks unexpectedly.

5.Connection mode is flange connection, clip connection, butt welding connection and lug clip connection.

Driving form is manual, worm gear transmission, electric, pneumatic, hydraulic, electro-hydraulic linkage and other actuators, which can realize remote control and automatic operation.