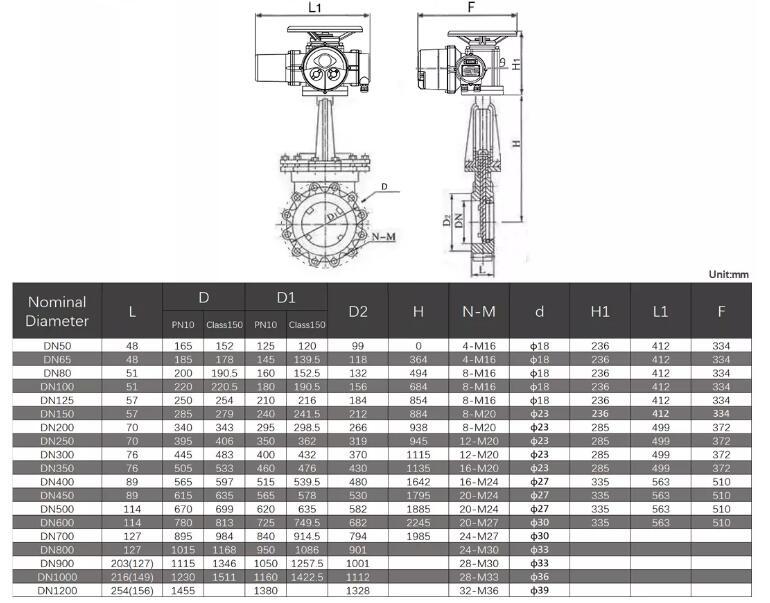

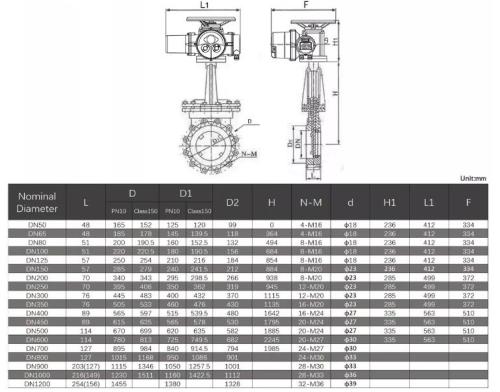

Custom Electric Knife Gate Valve DN50-DN600 PN10 For Sewage Plant

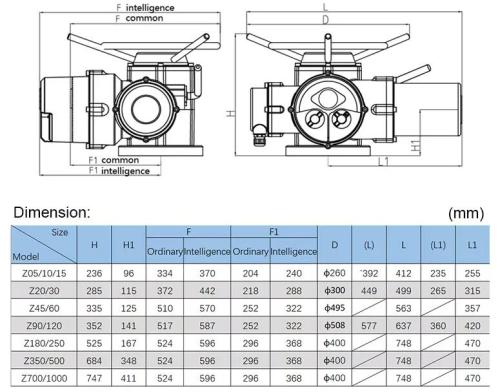

- Model

- DN50-DN600

Item specifics

- Standard

- PN10/PN16/CL150

- Sample

- Free

- MOQ

- 1PCS

- Certification

- ISO9001/PED/CE/EAC/TüV

- OEM

- YES

- Color

- Accept Custom

- Certificate of origin

- YES

- 3.1 Material test

- YES

- Visit the factory

- Real-time video

- Guarantee period

- 3 Years

Review

Description

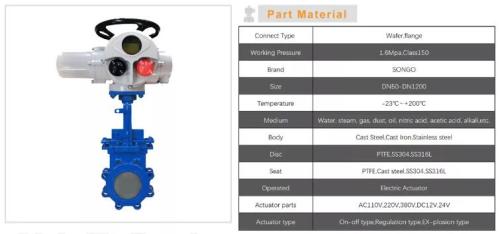

Custom electric knife gate valve

We offer knife gate valves with lever, handwheel, pneumatic actuator, ISO top flange for actuator or complete with electric or pneumatic actuator. The valve design permits a simple and rapid change of actuator.

Our knife gate valves are available with body of ductile iron and seat of NBR as standard, and optionally of other materials such as seat of viton, PTFE, EPDM, natural rubber or polyurethane depending on the service medium and the temperature at operation (NBR max. 80˚ C, PTFE max. 220˚ C, Viton max. 260˚ C). They are all treated with fusion bonded epoxy coating for optimal protection.

Knife gate valves with high quality materials and excellent design features

They are full bore valves permitting easy passage of liquid of whatever viscosity and there are no body cavities below the gate where the medium can collect. The valves are self-cleaning as particles will be pushed off the gate when opening the valve, and gate scrapers and deflector cones can be provided for particulate or abrasive media for extra protection of the packing gland. Also, the top packing gland is replaceable which enables replacement of the sealing without disassembly of the valve.

The design of our knife gate valves is simple and allows easy maintenance and cost effective installation. The valves are bi-directional and allow installation without any restrictions as to the direction of the flow. A protected sealing, high quality materials and a full, plain bore lead to a great performance and a long service life.

Features

▪ Replaceable top packing gland enables sealing replacement without disassembly of the valve

▪ The valve is self cleaning as particles will be pushed off the gate when opening the valve. For extra protection of the packing gland a scraper is available as an optional extra.

▪ Full bore with no reduction of the flow

▪ Plane bottom prevents sediment from being accumulated

▪ No cavity in the body and thus no risk of clogging

▪ Encaged stem with yokes prepared for mounting of micro switches and inductive censors

▪ Stem and gate connection is secured with self-locking nuts

▪ Supports integrated in the body casting protect the gate from deflecting under pressure

▪ Body of ductile iron with 100-150 μm UV resistant polyester coating, RAL 5017. Optionally of acid-resistant stainless steel or duplex

▪ Yokes of carbon steel with coating 100-150 μm of plascoat PPA 571 Aqua

▪ Gate, stem, bolts and nuts of acid-resistant stainless steel

▪ Washers under the bolts protect the coating

▪ Slim design and low weight

▪ Approved according to the 97/23/CE European Pressure Equipment Directive

▪ Approved according to the 94/9/94EC, ATEX Directive

▪ Available in larger dimensions

▪ Optionally in higher PN class