Installation instructions for butterfly valve piping

- Share

- From

- https://mp.weixin.qq.com/s/6vlNq6GZYJwI4aCDOa5NXA

- publisher

- Alex

- Issue Time

- Sep 7,2022

Summary

Installation instructions for butterfly valve piping

Installation instructions for butterfly valve piping

1. Weld the flange to the pipe and cool to ambient temperature before mounting the valve to the flange. Otherwise, the high temperature generated by welding will affect the performance of the elastic seat.

2. Edges of welded flanges must be lathed to smooth surface to avoid damage and elastic seat during valve installation. The flange surface must be completely free from damage and deformation, remove all dirt, dust and foreign matter, and avoid liquid leakage of valve and flange interface.3. Clean the flange and the inner cavity of the pipeline to completely remove the sputter, scale and other foreign bodies left by welding.

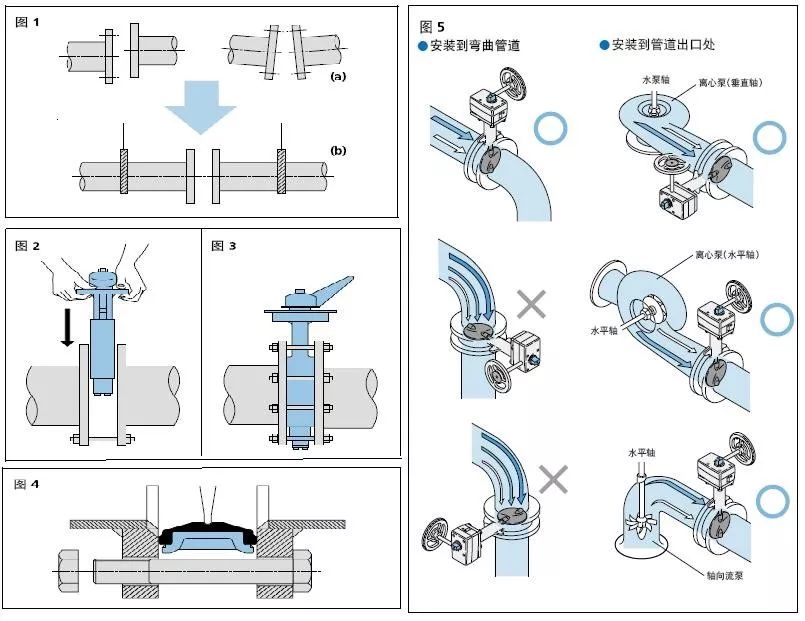

4. When installing piping between valves, accurate alignment of the center of the upper and lower water lines is essential for trouble-free operation. The imprecise center point shown in Figure 1 must be avoided.

5. When installing the valve, fix the positioning bolts at the bottom of the pipe at the same height to play a supporting role, and adjust the distance between the flanges until the two sides of the valve body are about 6-10 mm apart. Remember that the valve can only be opened from the closed position to the 10° position.

6. Insert the two bolts into the lower guide bar of the valve and install carefully so that the flange surface does not damage the elastic seat. (see figure 2)

7. Then insert the other two bolts into the guide rod above the valve, ensuring accurate center position between pipe and valve.

8. Open valve three times to check whether the contact between valve plate and flange is not smooth.

9. Remove the positioning bolts and place all bolts around the body in alternating diagonal tightening (see Figs. 3 and 4) until the flange touches the body. Refer to the table below for recommended torque values.

10. Install actuator to provide a support for valve to avoid twist of valve neck and reduce friction between valve and pipe.

11. Do not step on the valve neck or valve handwheel.

12. Do not install DN350 or larger valves upside down.

13. Do not install butterfly valves directly on check valves or pumps as this may cause damage upon contact with the valve plate.

14. Do not install valves on the downstream side of elbows and tapering tubing, or calibrate valves when flow rates change. In THIS CASE, IT IS RECOMMENDED TO INSTALL THE VALVE AT A DISTANCE OF APPROXIMATELY 10 TIMES THE NOMINAL DIAMETER OF THE VALVE.

15. Valve installation needs to take into account which disc will experience flow rate and pressure during the transfer of liquid